Technography of small-scale gold mining in the Amazon

Authors: Leontien Cremers and Luciana Massaro (2018)

Technography can be considered as an ethnography of technology. It is proposed by Jansen et al. (2011) and others as an interdisciplinary methodology for the detailed study of the use of skills, tools, knowledge and techniques in everyday life, especially for the integrative study of social-technical configurations. Where ethnography is used in the social sciences to account for the detailed description of human X human interaction, accordingly, technography can be regarded as a descriptive social science of technology that examines human X machine/tool interaction.

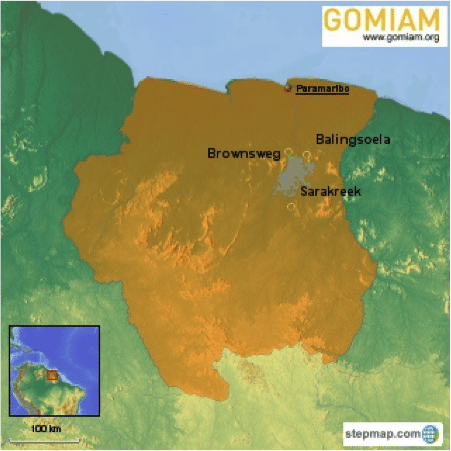

This methodology is useful within the GOMIAM project context, where both anthropologists and (mining) engineers have been working together on research and policy advice in the period 2011-2016 on several topics related to small-scale gold mining in the Amazon, with a focus on situations of conflict and cooperation in this sector. Mining technology is at the basis of the mining process, but it was clearly felt in the project that it could never be looked at without considering the human component and the wider socio-economic and political context at the same time. Therefore, the GOMIAM researchers set out to develop and execute a research methodology that we would like to call a technography of small-scale gold mining in four Amazon countries: Suriname, Brazil, Peru and Bolivia.

The main results of this research are presented below, but first some quick details on the methodology and research steps taken:

Methodology

In order to be able to execute comparative research in four different countries the following research elements were developed and written down in a manual:

- Questionnaire for miners (with multiple choice questions)

- List of questions for local expert miners (with open ended questions)

- A video assignment to be executed on each research location

- Guide for conducting group discussions based on the first technology research results

First step: Research in Suriname

First, the research was executed by a multi-disciplinary group of researchers in Suriname, in the period 13-22 January 2016. The group was composed of two mining engineers, a fishery engineer, an anthropologist, a geologist, a water engineer, two master students and a bachelor student of the mining group of the Anton de Kom University Paramaribo. This group managed to conduct in total 56 questionnaires (A.) with a group of 6 interviewees (MT, RF, BY, RB, SE,PC), around six interviews (B.) with local expert miners, shoot many videos of the mining practices (C.) in the research area and conduct two group discussions (D.). Besides, a technical characterization of the mining sites was done by the Brazilian mining engineer in the team, by means of an additional questionnaire, executed by him and the students.

Next step: Comparative research

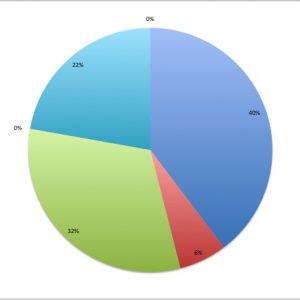

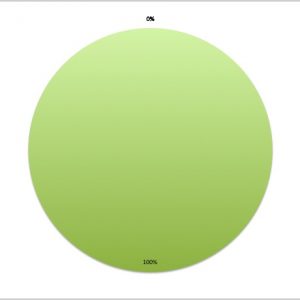

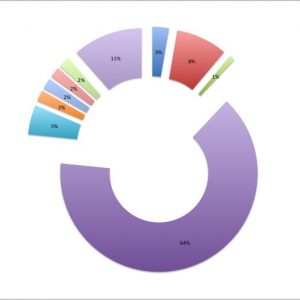

After this, the research methodology was shared with the GOMIAM country teams in Peru, Bolivia and Brazil. Here, resp. 30, 10 and 24 questionnaires were done with miners, also a number of videos were made.

This allows us to compare technology research outcomes in the different GOMIAM countries. The results are presented below, after presenting the four different research areas.

Description of the four research areas and its mining population

Results of the technography questionnaire

The process of gold extraction involves several phases and entails the use of several tools: from simple and manual ones (such as the gold pan), to more sophisticated and mechanized ones (such as the excavator). This technography tries to give more insight in these phases and features in the countries under study.

The choice of a particular extraction process and related tools depends mainly on the type of gold deposit. In geology, the colluvial deposit is a primary sediment constituted by gold embedded in quartzite rocks; whereas the alluvial deposit is a secondary sediment where gold, due to rock erosion, is washed away and deposited along watercourses (Cleary, 1990). Small-scale gold mining is usually devoted to secondary deposits as the gold, concentrated by gravity processes, is free and easy to extract. But also small scale mining practices in primary deposits can be found in the countries under study.

For this technography, the following phases and aspects were identified and querried:

- Prospection

- Opening a mine pit

- Gold extraction

- Gold concentration

- Socio-cultural issues

- Visions for the future

1. Prospection

Deciding where to dig a mine represents the first phase of the whole operation and identifying a mining target requires gathering data about the geology, the chemistry and the physics of a specific area (Moon et al., 2006). Usually, knowing the size and quality of a deposit inevitably implies two types of underground investigation: a prospection and a physical exploration (Lins, 1992).

In order to find the exact target of drilling, the prospection phase requires a detailed report based the geological mapping of the area. The procedure of geological mapping is based on the location of the surface mineralization and although this is usually assessed by geologists, it can also be determined by less formally trained people. In fact, the outcrop of a mineral deposit can be identified by some anomalies or specific characteristics on the ground (such as a very different appearance of parts of soil from the surrounding rocks). Interestingly, despite the accuracy of more high-tech survey methods, there is no formal obstacle that hinders a miner from the discovery of a deposit (Lins, 1992). Often, having an experienced “eye for ore” constitutes the only requirement (Moon et al., 2006). Artisanal gold miners commonly rely on this kind of reconnaissance techniques as the high complexity of the task and the prohibitive operative costs do not allow other more sophisticated methods.

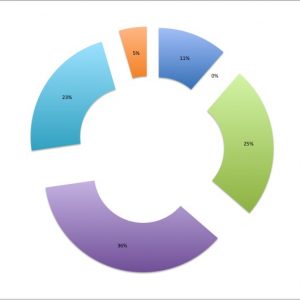

1.1 How do you decide where to mine?

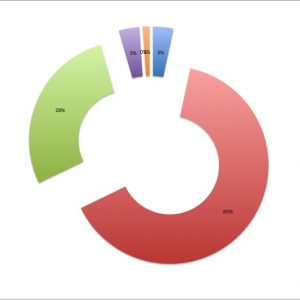

1.2 Which tools do you use?

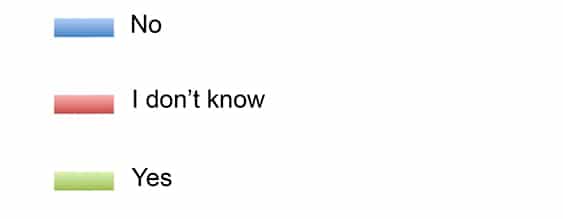

1.3 Would you like to improve this method?

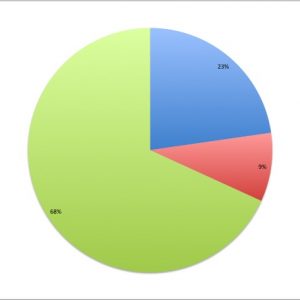

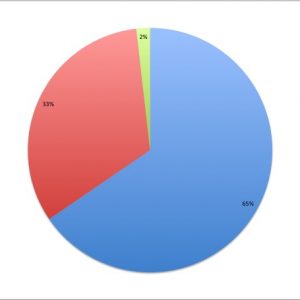

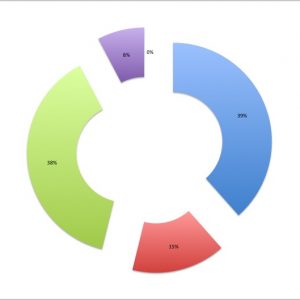

Suriname

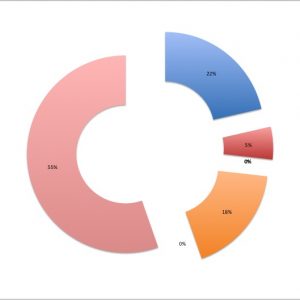

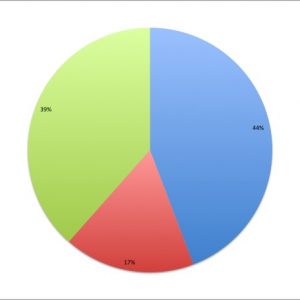

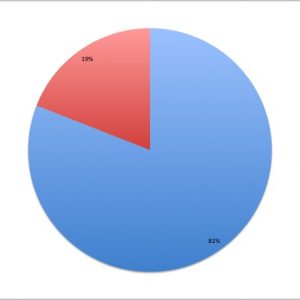

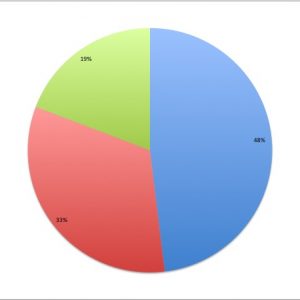

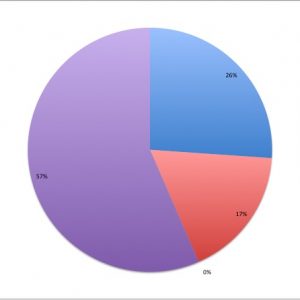

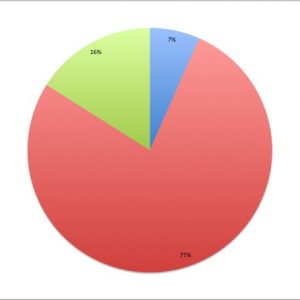

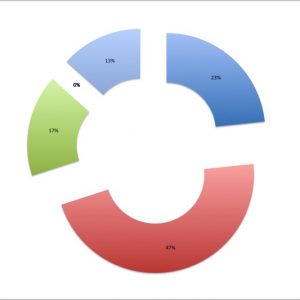

In Surinam, 39% of the respondents would like to change their prospection methods, saying there are better methods, experts could be invited or by using an excavator to speed up the process. The 44% saying they do not want to change, claim there is no other or better method, or that they are used to doing it this way. (N=52)

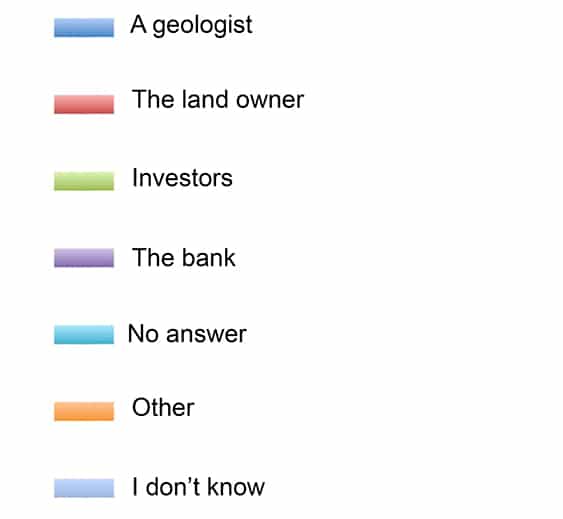

1.4 Who can help to improve prospection?

2. Opening a new mine pit

The geological anomalies identified during the prospection phase need to be confirmed with a following physical exploration of the soil. During the prospection, any deep inspection is formally required, whereas the physical exploration demands an underground examination through pitting, trenching and specific drilling. Often these actions are destructive to the environment as target sites may be deforested and left exposed without vegetation or any topsoil left (Hilson, 2002). Once miners have decided where to mine, the forest cover and top soil are removed and a mining pit is formed.

2.1 Which tools you use to open a mine pit?

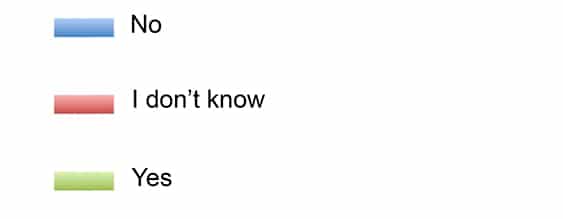

2.2 Would you like to improve this method?

2.3 Why don't you improve this method?

3. Gold extraction

Most gold extraction found in the countries under study is hydraulic mining on secondary deposits. Seccatore and de Theije (2017, p.110) describe the process of extraction on secondary deposit as follows: “in hydraulic mining an engine is connected to a double-action pump, which provides pressing and suction actions. The pressing action feeds a water monitor with a high-pressure flow of water. An operator manoeuvres the monitor to direct the water jet on the soil to loosen the consolidated or semi-consolidated material. The pulp of water and loose material is then sucked up a pipe by the suction action of the pump. The pulp is then pumped over sluice boxes. An excavator usually removes the overburden (generally silt and clay), exposing the material of interest (usually sand or sandy silt) that is mined by hydraulic means”.

3.1 Which tools do you use for extraction?

3.2 Where do you get these tools?

3.3 Why did you choose this method?

3.4 Would you like to improve this method?

4. Gold concentration

“Two systems of mineral processing may occur: i) simple sluice boxes or ii) crusher, sluice and copper plates. With the first method, the excavated material is directly pumped in pulp with water onto sluice boxes. Sluice boxes can be covered with carpets or metal mesh or a combination of both. Mercury can be added directly in the sluices or later in the concentrate extracted from carpets and metal mesh. With the second method, the excavated material is crushed in a hammer crusher and then sent in pulp to flow over sluice boxes and copper plates” (from Seccatore and de Theije, 2017, p.110).

After this a process of concentration takes place, using buckets, ponds or even just a gold pan to concentrate and collect the gold or gold-mercury amalgam.

4.1 How do you process the gold-containing material?

4.2 Would you like to improve this method?

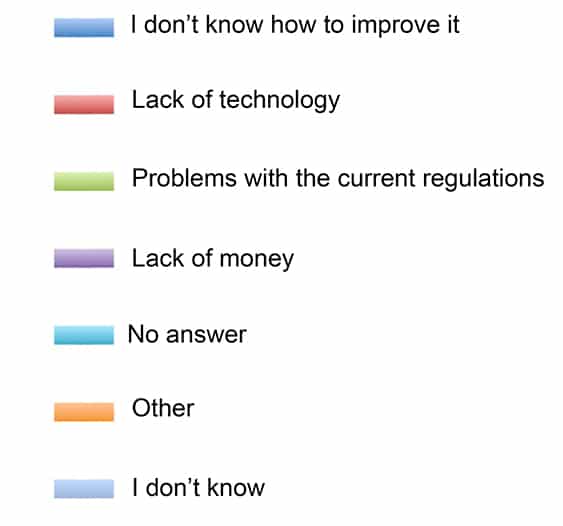

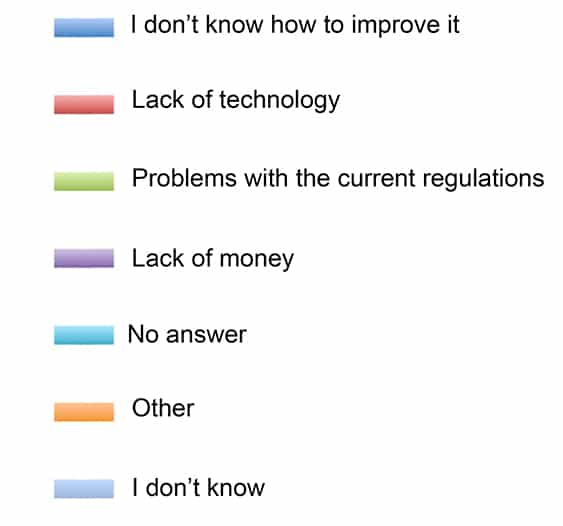

4.3 Why don't you improve it?

4.4 Do you use an enclosed recipient to wash the gold concentrate?

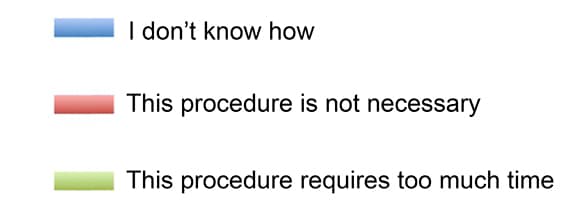

4.4b Why don't you use an enclosed recipient to wash the gold concentrate?

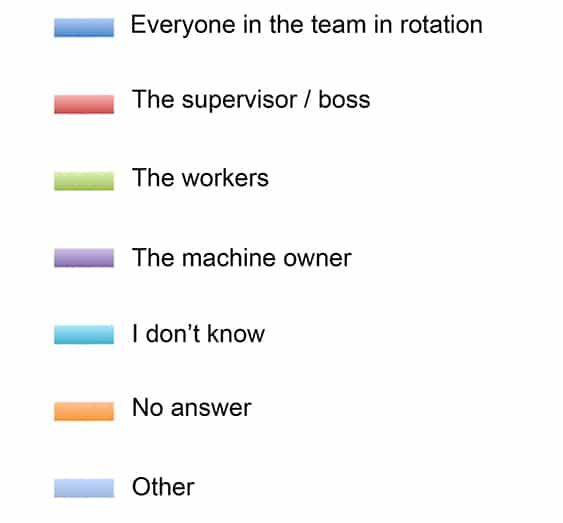

4.5 Who processes the gold concentrate?

4.6 Do you use personal protection when processing the gold concentrate?

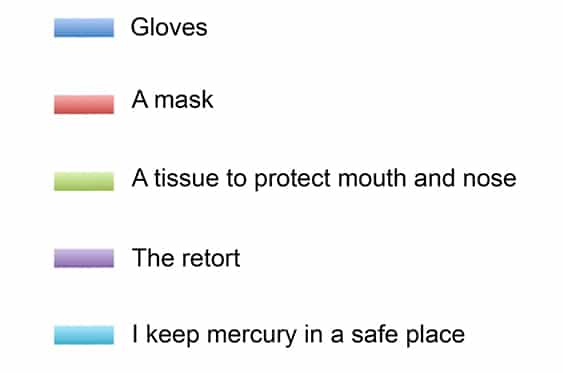

4.6b If yes, what do you use?

4.7 If not, why not?

Questionnaire results for 5. Socio-cultural issues

As stated, the technological features and choices miners make cannot be seen separately from the wider socio-economical and cultural context. That is why a number of socio-cultural questions were added to the questionnaire, in order to get a better feel of miners’ motivations and driving forces.

5.1 Do you maintain your family with your mining income?

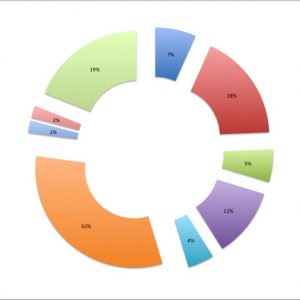

5.2 How do you invest your money?

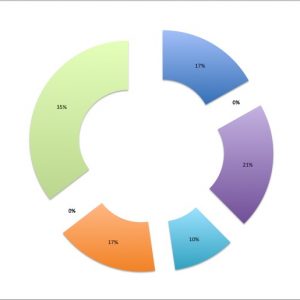

5.3 Whose land do you work on?

Questionnaire results for 6. Visions for the future

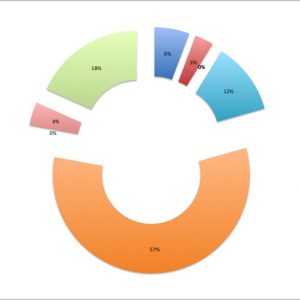

6.1 How do you see the future of small-scale gold mining in your country

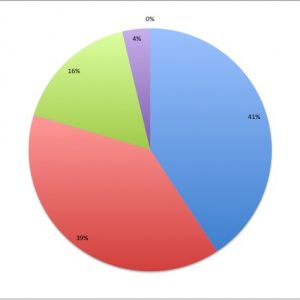

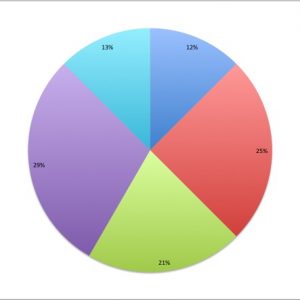

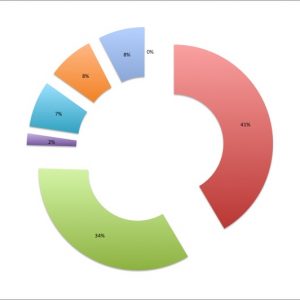

6.2 How could small-scale gold mining in your country be improved in the future?

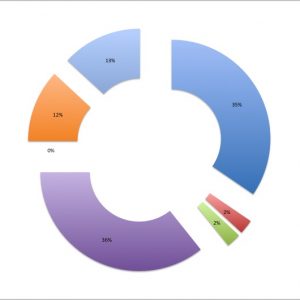

Suriname

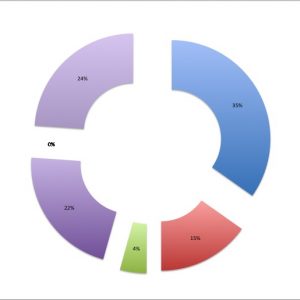

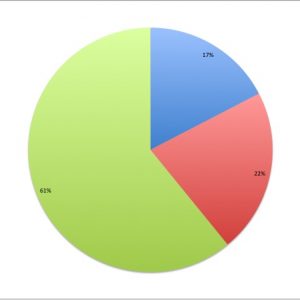

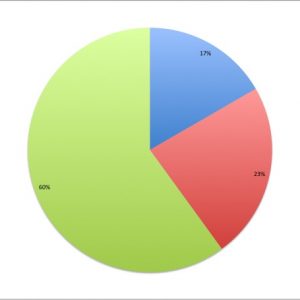

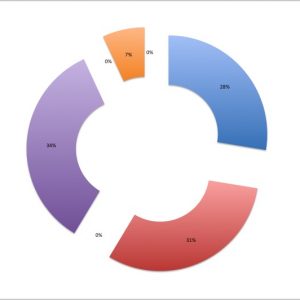

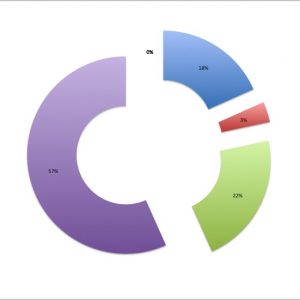

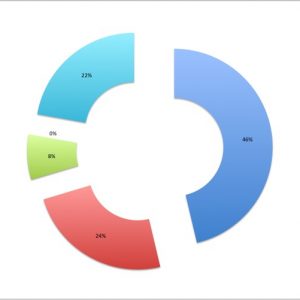

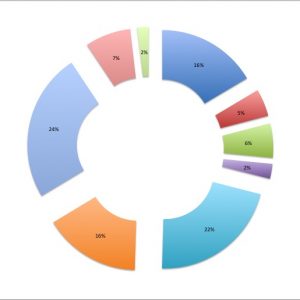

It is clear that many different answers were given to this question also in the different countries. In Suriname, 24% says they do not know how to improve, 22% says it could be improved by improving regulation, 16% sees improvement possible through the education of miners on regulatory issues. (N=50)

6.3 How would you like to contribute?