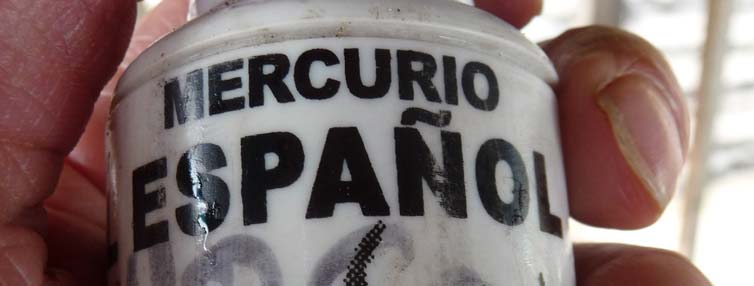

Mercury is traditionally used in small-scale mining to enhance the gold recovery. Gold binds with mercury to form a heavy amalgam. This way it is possible to collect the very small gold particles that would otherwise have washed away. After operating, the two materials are separated again by heating the amalgam, which vaporizes the mercury and leaves the solid gold.

Mercury vapor is toxic and can cause neurological diseases and other health problems. Moreover, when the fluid mercury is released into the environment, it can turn into the more toxic methyl-mercury. This climbs up the local food chain. A risk for both the miners and local communities.

There is a technique in which the mercury release is minimalized. Heating the amalgam can be done in a closed system, a retort, instead of in the open air. The retort catches the mercury vapor, which, after cooling down, can be re-used.

Between 2002 and 2007, the United Nations Industrial Development Organization (UNIDO) initiated the Global Mercury Project (GMP) in collaboration with governments and NGOs, to promote knowledge on gold mining related to health and the ecosystem, and to reduce mercury pollution and exposure caused by mining activities.

This project intended to introduce cleaner technologies, to train miners, to develop regulatory capacities within national and regional governments, and to conduct environmental and health assessments. Brazil was the only Latin American country participating in the project, in the Tapajós region. As a result of the project, the use of retorts has more than doubled. Still almost 60% of all small-scale miners sticks to the ‘open system’ and mercury remains the main means to separate the gold from other material.

View:

The Minamata Convention on Mercury, the implementation of UNITAR (2016, Ministerio de Ambiente Peru)

Informative video on mercury use in mining, and its effects. (2014, CSA-UPCH – en Español)

Video How to make a retort. (2015, EDANA – en Español)

Read more:

- How to make a retort by Wanamei

- MercuryWatch.org

- Fairtrade & Fairmined gold.

- Mercury contamination in the Amazon Basin.

- Telmer, K. & Stapper, D. (2012). A practical guide. Reducing mercury use in artisanal and small-scale gold mining. United Nations Environment Programme.

- Veiga, M. et al (2014). Review of barriers to reduce mercury use in artisanal gold mining.